F850

Online MDA testing equipment

Automatic burning of mid-to-high-end electronic products

Product Positioning & Application

Positioning: Automatic programming of chips such as MCUs, domain controllers, flash memories, and logic memories in PCBA (Printed Circuit Board Assembly) of mid-to-high-end electronic products, and the testing functions such as MDA (Manufacturing Defect Analysis), FCT (Functional Circuit Test), and Bscan (Boundary Scan) can be extended.

Application: High-end 3C products, automotive electronics, mobile phones, communication base stations, computer terminals, medical electronics, and new energy.

Supports "Multiple" Chips

- General-purpose programmer supports most mainstream chip products.

- Supported programming protocols: SWD, DAP, UART, JTAG, SPI, I2C, etc.

- Supported chip types: Microcontrollers, Serial Memories, CPLDs, FPGAs, Parallel Memories.

- One programmer can support the programming of 8 chips simultaneously. For more parallel programming, the cascading method can be adopted.

Product Advantages

Safe and Reliable

It uses an X-shaped downward pressing mechanism, featuring high flatness, uniform force distribution, and stable probe contact.

Ultra-fast and efficient

It is equipped with a quad-core parallel testing architecture, supports the expansion of up to 12 Pin cards, and provides 1,536 testing channels.

Dual-mode all-rounder

It is the first in the industry to integrate programming and MDA testing functions. It is compatible with both online and offline modes, easily adapting to the requirements of various production scenarios.

Cost Saving

It has a lower average cost per machine model.

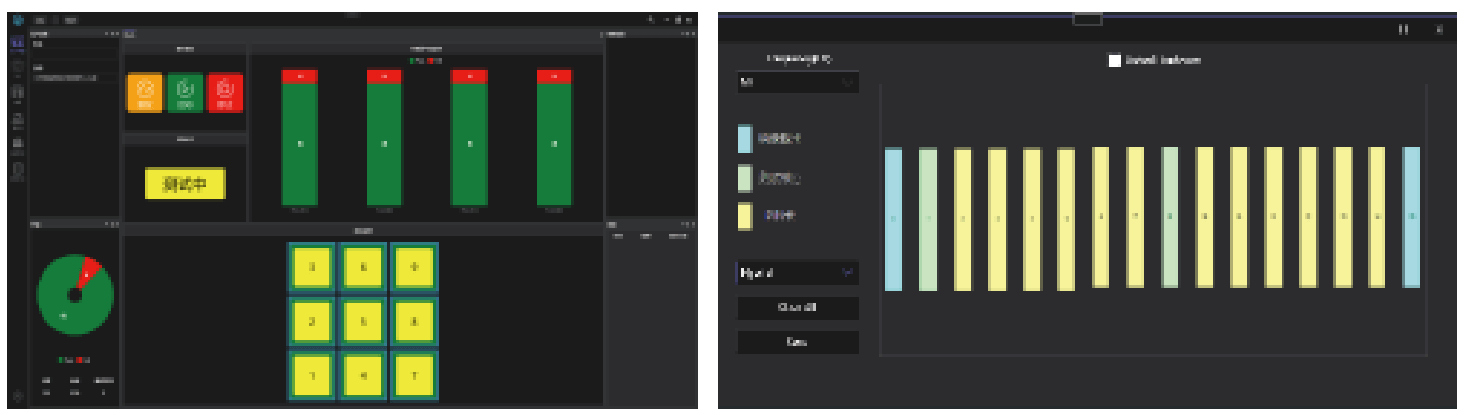

Platform Software Design

Platform-based software design with graphical, visual status monitoring and programming test data presented in report form; supports independent configuration of programming procedures for each chip, and flexible configuration of multifunctional test slots.

In/Off Line Mode

Supports In/Off Line (online/offline) mode based on the user's production line wiring requirements.

- In-Line (Online)

Can interface with front and rear track lines or up-and-down loading machines for automatic production line testing. The board entry and exit direction can be set according to the user's actual situation (left entry, right exit; right entry, left exit; left entry, left exit; right entry, right exit, etc.).

- Off-Line (Offline)

Manual testing supports side-entry board handling.

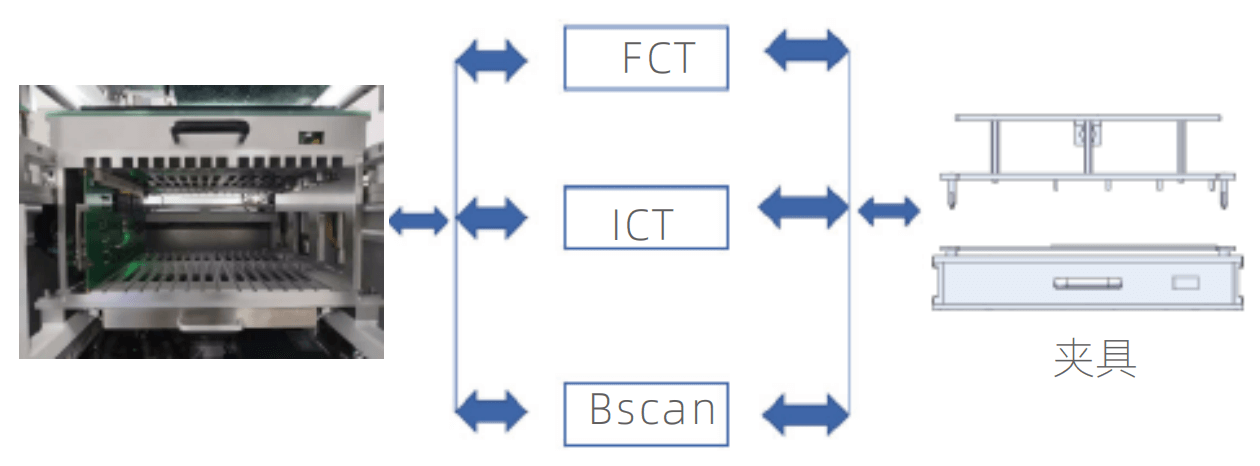

Expansion Modules

Slot design can be expanded to add more programming channels. Users can complete all settings in the software interface. It supports the addition of ICT/FCT/Bscan modules as needed.