On the evening of April 28th, IFREE's live broadcast themed "Innovation in Flying Probe Testing Technology and New Product Launch" successfully concluded! Many industry partners gathered in the live broadcast room to witness how domestic flying probe testing equipment breaks through technical barriers, reshapes the market landscape, and unlocks full-scenario testing solutions from "R&D verification" to "mass production". Here are the key points to review this technology feast full of valuable insights!

I. Industry Insights: From "Substitution" to "Leadership", How Does IFREE Define the New Future of Flying Probe Testing?

1. Accurately Capturing Market Gaps: Seven years ago, flying probe testing was monopolized by imported brands with high prices. In scenarios such as 5G high-frequency board testing, multi-variety small-batch production, and R&D prototyping, traditional ICT equipment was difficult to胜任. IFREE keenly insight into the advantages of flying probes, such as "no fixtures required, flexible and efficient, direct pad testing", and broke through technical blockades with domestic innovation.

2. Rewriting the Competitive Landscape: Today, IFREE's flying probe equipment performs comparably to international brands and promotes the "popularization" of flying probe testing with price advantages, allowing small and medium-sized manufacturers to also enjoy high-end testing technologies.

3. Expanding New Application Frontiers: By integrating LED testing and programming functions, and developing segmented products such as desktop X2D (laboratory/repair scenarios), bare board/FPC testing-specific X2F, and semiconductor substrate testing X2S, IFREE has expanded the flying probe market from "niche essential need" to broader industrial scenarios.

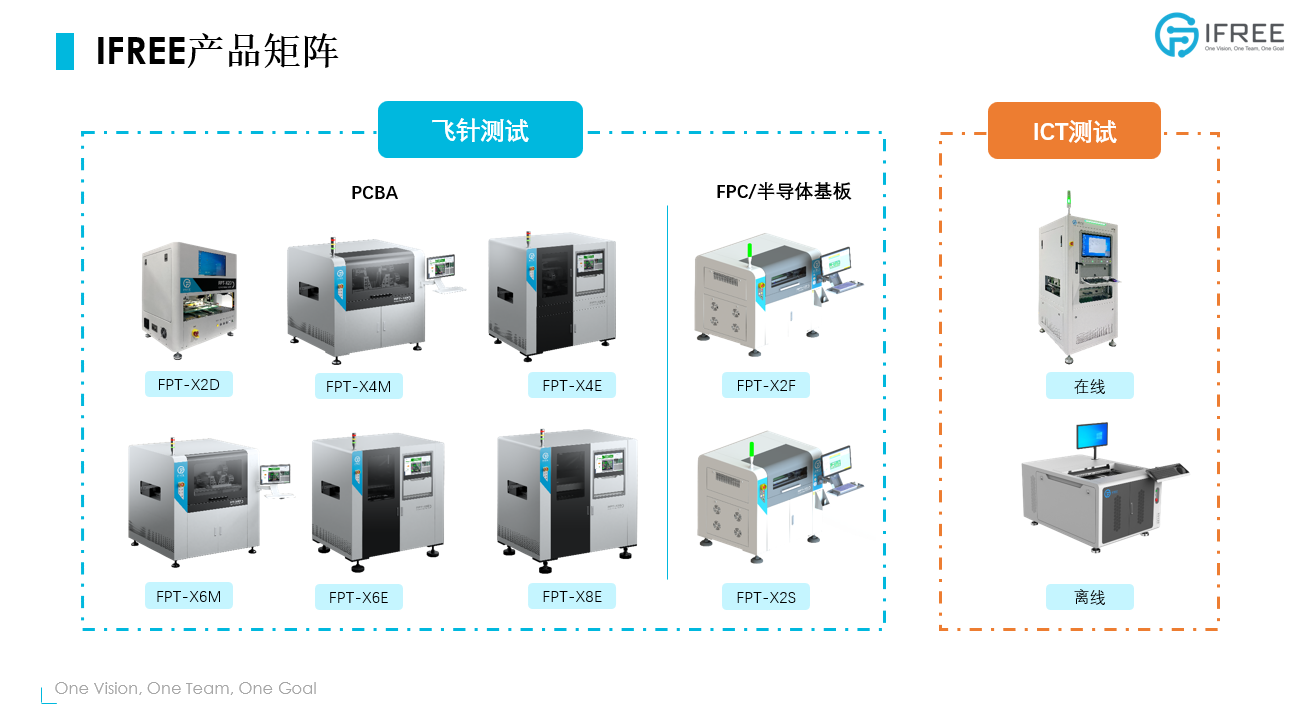

II. Product Matrix: Full-Scenario Coverage, from "Hardcore Performance" to "Ultimate Usability"

1. Flying Probe Testing Family: Flexible Adaptation, Precision and Efficiency

Classic Models (E/M Series): The E series serves as a performance benchmark, using linear motor motion mode with a proximal module to effectively reduce the impact of long-line signals and achieve more accurate testing; the M series focuses on cost-effectiveness, using lead screw transmission with slightly lower precision than the E series but more affordable prices. IFREE equipment uses carbon fiber materials, which are high-strength and lightweight, and supports optional LED and OPP configurations.

Desktop X2D: Compact size, low space occupation, low acquisition cost, and low operation and maintenance costs, suitable for R&D prototyping, production line sampling, and maintenance.

X2F/X2S: 2-probe systems for PCB bare board/FPC testing. Manual loading and unloading, offline use, fixed by vacuum adsorption table. X2F can be upgraded to X2S by integrating precision instruments to achieve semiconductor substrate testing.

2. ICT Equipment: Online Programming + Testing Integration

F850 Online MDA Testing Equipment: This is an online ICT device with powerful chip programming functions, capable of online parallel programming of various chips such as MCUs, domain controllers, flash memory, and logic memories. The built-in programmer supports multi-channel parallel processing, with a single programmer handling up to 6 chips simultaneously, and a maximum of 2 programmers for 12-channel parallel programming, supporting multiple communication protocols. On the software level, it adopts platform-based software design with graphical visualization status monitoring to display real-time equipment operation status and automatically generate programming test data reports for data management and analysis. With the intelligent EasyDFT software, it can automatically parse design files and generate testing strategies to improve test coverage with one click. Additionally, it supports independent configuration of programming procedures for each chip to meet diverse needs. The device supports analog testing and is also called an MDA device according to industry conventions. It is equipped with 12 multifunctional test slots, each with 128 test points, providing a maximum testing capability of 1,536 points to ensure precise testing.

III. Q&A Session: Answers to Your Concerns About Flying Probe Testing!

Q: How to choose between flying probe and ICT?

A: Choose flying probe for R&D prototyping/multi-variety small batches (no fixtures, fast programming); choose ICT for mass consumer electronics (efficiency priority). Flying probe is more flexible in special scenarios (high-frequency boards, few test points).

Q: Is domestically developed equipment reliable in performance?

A: Absolutely reliable. 100% domestically manufactured with independent intellectual property rights, one-piece machine frame for anti-vibration, Hyper BOX intelligent controller for multi-axis synchronization, and software supporting AI algorithm-optimized testing strategies.

Q: What are the characteristics of the testing software?

A: Intelligent and user-friendly. Adopts a "brain + cerebellum" architecture, where the "brain" establishes mathematical models through classic circuit learning, calculation, and simulation for testing decision-making; the "cerebellum" controls motion driving and path planning for precise high-speed motion control, combining to output testing results. AI is the development direction of the software.

Q: Price and service?

A: Absolute cost-performance advantage compared to imported brands, with no hidden costs; provides MES system integration, round-the-clock on-site after-sales service, sufficient spare parts, and an experienced technical team.

From breaking monopolies to defining standards, IFREE has written a new chapter in domestic substitution in the electronic testing field with "innovation" as its core. Whether it's the "agile probe" on the R&D desk or the "high-efficiency equipment" on the production line, we always believe that making high-end testing technology accessible is the true industry innovation.

IFREE looks forward to joining hands with you to explore the infinite possibilities of electronic manufacturing!