On March 13th, Chongqing, the mountainous city, hosted a grand event in the electronics industry - the "Chongqing Intelligent Manufacturing User Alliance & Chongqing Electronics Industry Intelligent Manufacturing Annual Conference." As an important participant in the industry, IFREE attended this event, gathering with numerous experts and scholars in the field to contribute to the rapid advancement of China's electronics industry.

At the forum, Mr. Zhou Bin, the Marketing Director of IFREE, delivered a wonderful speech. In the electronics manufacturing industry, flying probe testing, as a critical link to ensure the quality of electronic products, is of self-evident importance. With electronic products developing towards miniaturization and high integration, flying probe testing faces many severe challenges. IFREE has the courage to break through, investing heavily in establishing a professional R&D team. With profound professional knowledge and rich practical experience, the team has deeply studied all aspects of flying probe testing technology, simultaneously optimizing both hardware design and software algorithms through repeated refinement.

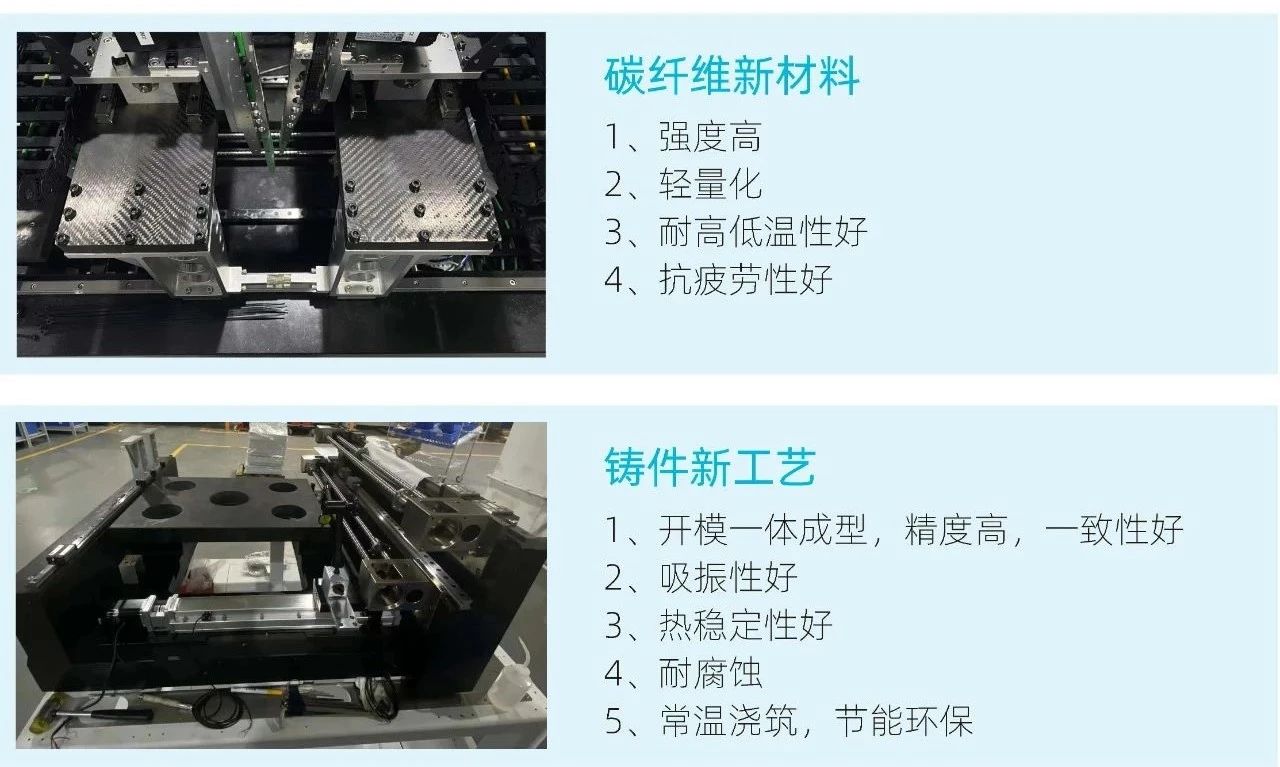

In terms of hardware, after extensive experiments and comparative analyses, IFREE has selected mineral castings and carbon fiber boards as the main structural materials. Mineral castings have excellent vibration damping performance, which can effectively absorb the vibrations generated during equipment operation, ensuring the stability of the flying probe during testing and reducing test errors caused by vibrations. Carbon fiber boards stand out for their high strength and low density, enabling the equipment to withstand higher-intensity usage frequencies. During long-term, high-frequency testing operations, the equipment can still maintain stable operation, greatly extending its service life and reducing customers' equipment maintenance costs.

In terms of software algorithms, the R & D team has invested a great deal of effort. Through the analysis and simulation of massive amounts of test data, they continuously optimize the algorithms. The optimized algorithms are highly intelligent. Operators only need to perform simple parameter settings, and the software can automatically plan the best test process and flying probe movement path according to the type of circuit board and test requirements, greatly reducing the operation difficulty and improving test efficiency. At the same time, the algorithm can quickly and accurately analyze and process the data collected by the equipment. It can deeply mine the test data in a very short time, not only accurately locating various problems on the circuit board, such as component failures and线路短路, but also helping customers discover potential problems and optimization spaces through the correlation analysis of the data.

IFREE has won wide acclaim for its excellent product quality and outstanding technical level. Its customers cover multiple industry sectors such as EMS, military, communications, vehicle electronics, aerospace, semiconductors, new energy, and industrial control. At the event site, after the IFREE guest's speech and sharing, there was a crowd in front of the IFREE booth. Many participants actively went there to consult and communicate, eager to learn more about IFREE's products and services.

Intelligentization and digitization are the general trends in the development of modern manufacturing. With the vigorous advancement of intelligent manufacturing in China, IFREE will always focus on the core competitiveness of technology and innovation in the future, committing to researching and developing more advanced technologies and products to create higher value for customers.