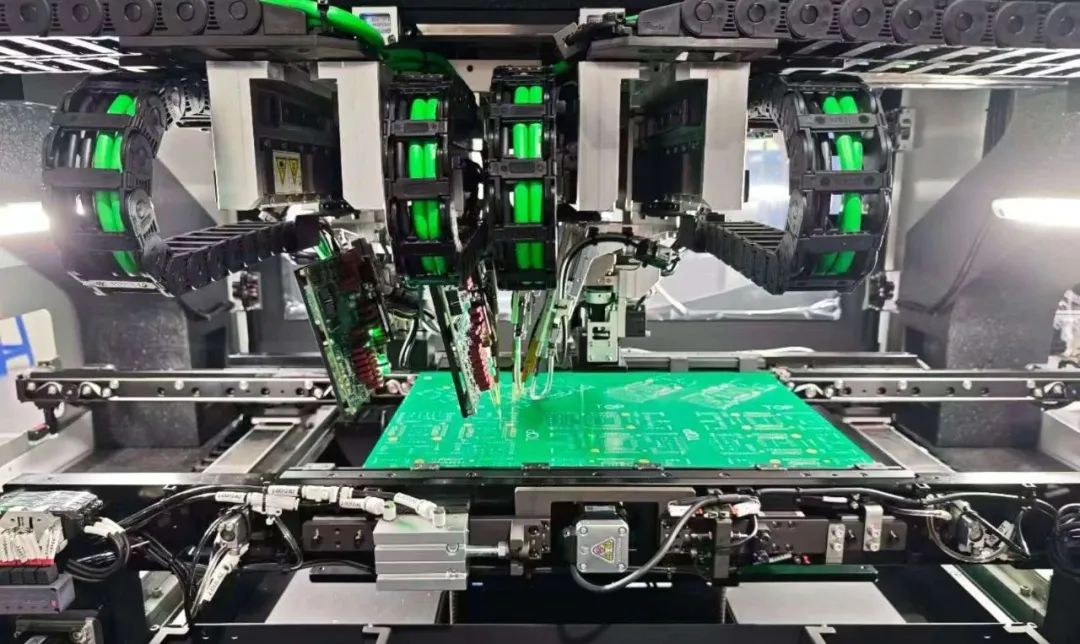

In the current era of rapid development in electronic manufacturing, testing accuracy directly affects the performance and quality of electronic products. Are you still troubled by high loss in high-frequency signal testing and inaccurate testing of tiny components? The IFREE Flying Probe Near-Field Testing System provides a new solution for high-precision PCBA and semiconductor testing!

I. What is Flying Probe Near-Field Testing?

Flying probe near-field testing achieves extremely close contact between the excitation source and the Device Under Test (DUT) by optimizing the probe path and signal transmission structure, significantly improving the testing accuracy of high-frequency signals and high-speed digital circuits. It has two core characteristics:

-

Close contact with the signal source: Shortening the distance between the signal source and the device under test reduces issues such as delay, attenuation, and reflection during signal transmission, making signal transmission more stable.

-

Precise positioning of test points: The probe directly contacts the key nodes of the device under test, avoiding interference from parasitic parameters caused by long leads and ensuring more accurate test results.

Compared with traditional far-field testing, near-field testing can improve testing accuracy, reduce external electromagnetic interference, capture signal parameters more accurately, simplify the calibration process, and has strong practicality.

II. Four Core Advantages of the IFREE Flying Probe Near-Field Testing System

1. Excellent performance in high-frequency testing

It supports GHz-level signal testing and can effectively reduce signal transmission loss and reflection. Whether it is the testing of high-speed signals in 5G communications, Radio Frequency (RF) circuits, or High-Density Interconnect (HDI) boards, it can accurately detect signal details and meet the testing needs of high-end electronic products.

2. Accurate testing of tiny signals

With the original probe positioning algorithm and low-noise design, even weak signals and high-impedance nodes can be stably tested, without missing any tiny defects, ensuring accurate and reliable test results.

3. Flexibility, efficiency, and cost reduction

There is no need for custom fixtures, and it can quickly adapt to multi-variety, small-batch production and various complex testing requirements, greatly reducing testing costs, shortening the testing cycle, improving production efficiency, and increasing corporate profits.

4. Domestic independent research and development, safe and reliable

The hardware and software platforms are fully independently developed, meeting the strict requirements of high-end manufacturing for the safety and reliability of testing equipment, getting rid of dependence on foreign technologies, and providing strong technical support for China's electronic manufacturing industry.

As a leading domestic provider of electronic testing technology, IFREE has overcome one difficulty after another in electronic testing with solid technology. The IFREE Flying Probe Near-Field Testing System has been successfully applied in fields such as consumer electronics, automotive electronics, and aerospace. From the accurate capture of high-frequency signals to the reliable testing of tiny components, from the effective control of costs to the independently controllable technical guarantee, all demonstrate extraordinary strength. IFREE looks forward to working with you to jointly open a new era of efficient and accurate electronic testing!